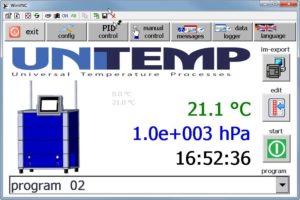

UniTemp RSO-200 Reflow Solder Oven

Reflow Solder Oven Technical Data for RSO-200:

- Loading area (max. part size): 200x170x40mm (WxDxH)

- Quartz glass process chamber (fix mounted), incl. graphite susceptor

- with integrated gas- in- and outlet

- 1 Mass Flow Controller for Nitrogen 5 nlm is standard

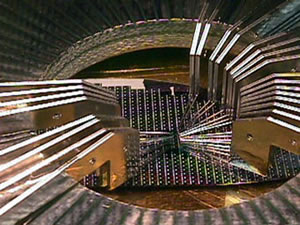

- heated by 12 Infrared lamps ( 9kW)

- bottom heating

- vacuum for external pump system (up to 10exp.-3 hPa, optional RSO-200-HV up to 10exp-6 hPa)

- SPS (PLC) controller, SIMATIC

- 50 programs with 50 steps each storable

- 7″ Touch Panel for comfortable programming and process control

- Ethernet interface

- Max. Temperature: 650 °C

- Ramp up rate: better 10 K/Sec

Ramp down rate: T=600°C to 400°C max. 200 K/min

T=400°C to 100°C max. 30K/min - Temperature control by thermocouple

- Cooling: Water cooling required (option)

- Electrical connection: CEE 16 A (3x230V, 3 Phase, +N, +PE)

- Weight: about 55 kg

- Dimension: 505mm x 504mm x 460mm

| Options and accessories | |

|---|---|

| RSO-200 | Basic unit |

| RSO-GT | Graphite tray with cover |

| RSO-MFC | Additional gas line with mass flow controller (max. 4 gas lines) |

| MP | Membrane pump for vacuum up to 10 mbar with manometer |

| MPC | Chemical Membrane pump for vacuum up to 10 mbar with manometer |

| RVP | Rotary vane pump for vacuum with oil filter up 10exp3 hPa |

| RSO-FA | Formic Acid Option |

| RSO-H2 | Module for using 100% Hydrogen including one mass flow controller |

| RSO-H2S | Safety device to prevent uncontrolled emission of Hydrogen |

| RSO-PC-200 | add. 200mm oven chamber ("double-chamber oven") |

| RSO-TC | add. thermocouple for measure on device (plugged in chamber) |

| WC III | Closed loop water cooling system (stand-alone) |

Download (information): RSO-200