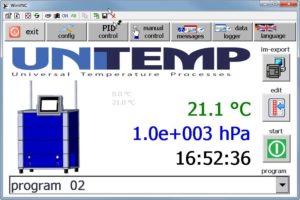

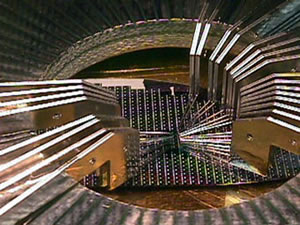

UniTemp RTP-100, front loading

Rapid Thermal Vacuum Process Oven with ramp-up rate up to 150 K/sec.

Key features are

- good temperature uniformity

- precisely controlled ramp-up rates and fast ramp-down rates

- low process turnaround

- comfortable gas control

- table top system with small foot print

Multipurpose table top unit with front loading drawer for the following applications:

- excellent tool for various semiconductor processes

- implementing of new semiconductor processes

- prototype research

- quality control

- annealing

- Rapid Thermal Processes

- SiAu, SiAl, SiMo alloying

- low k dielectrics

- post implanting annealing

- copper paste firing

- resistor paste firing

- other processes on demand

Technical Data:

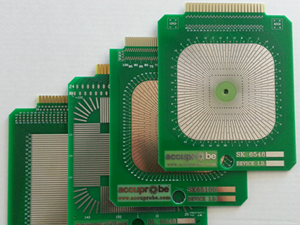

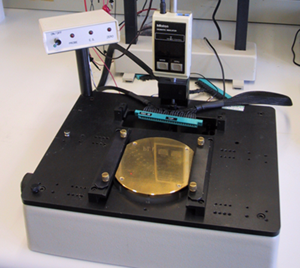

- for single wafer up to 100 mm (4″) or 100 mm x 100 mm substrate size

- process chamber made of quartz glass

- with integrated gas in- and outlet

- incl. one process gas line with Mass Flow Controller for Nitrogen (5 nlm = norm liter per min.)

- heated by 18 infrared lamps (20 kW)

- top and bottom heating (can be choosen)

- vacuum capable for external pump system (up to 10E-3 hPa, for up to 10E-6 hPa: see RTP-100-HV)

- SPS (PLC) process controller with 50 programs and up to 50 steps each (ethernet interface), SIMATIC

- 7″ touch panel for easy programming and process control

- max. temperature 1200 °C

- temperature control by thermocouple

- water cooling required

- electrical connection type: 32 A CEE plug (3x 230 V, 3 Phase, N, PE, 20 kW)

- dimension oven: 504 x 504 (700) x 570 mm (w x d x h)

- weight: 55 kg

The oven will be programmed by a Siemens SPS (PLC) controller. This allows the storage of 50 programs with saving all temperature profiles and segments.

Options and accessories like water cooler, additional flow meters, additional gas lines, additional thermocouple etc. are available on request. This tool

is for various applications and customers. The small size allows comfortable loading and unloading of the chamber. The oven can be easily placed on

a standard laboratory table.

| Options and accessories: | |

|---|---|

| RTP-100 | Basic unit with 1 MFC for Nitrogen (5 nlm) |

| RTP-MFC | Mass Flow controller (max. 4 in total) |

| VAC I | Vacuum up to 3 hPa incl. Vacuum sensor and valve (excl. Pump) |

| VAC II | Vacuum up to 10E-3 hPa incl. Vacuum sensor and valve (excl. Pump) |

| MP | Membrane or diapgrahm pump |

| RVP | Rotary vane pump |

| RTP-Ox | Oxygen level measurement |

| RTP-MM | Moisture level measurement |

| RTP-H2+H2S | Hydrogen Module to use 100% Hydrogen with safety device incl. MFC |

| RTP-SW | Switchbox for chiller and/or vacuum pump |

| RTP-TC | Add. Thermocouple to measure on device (max. 1 pc) |

| RTP-VCR | VCR connectors and lines (on request) |

| WC III | Closed loop water cooling station |

| RTP-GP | Graphite Plate or susceptor (SiC coated: on request) |

| RTP-100-PC | additional oven chamber for usage with one process controller unit (double pack oven) 100 mm |

| RTP-QR-50 | Adapter for 50 mm wafer size |

| RTP-QR-75 | Adapter for 75 mm wafer size |

Download (information): RTP-100