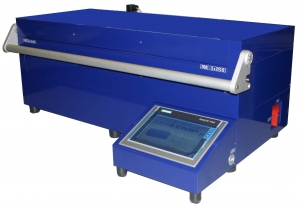

UniTemp VSS-300-CAB

Vacuum Reflow Solder Oven for up to 300 x 300 mm substrate size and temperature up to 450 °C and high vacuum up to 10E-6 hPa

Application:

Perfect for solder processes with substrate size up to 300 mm x 300 mm.

Due to the gas sealed separation of the working capacity (chamber) from the lamp fields this is a perfect tool for contaminating processes. The chamber parts can be easily cleaned.

Through the chamber walls there can be led different feed throughs, like window for optical measurement tools, thermocouple feed through, gas inlets, etc.

The process cycles are very short due to fast reaching of vacuum with 10exp.-3 hPa.

Here are the most feasable applications:

Processes using also other contaminating processes possible and all other applications of a Reflow Solder oven are oblitgatory,like:

- Solder Reflow with and without flux

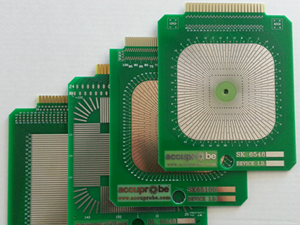

- Wafer bump and solder ball reflow

- Flip Chip

- Encapsulation and sealing of housings

- High Power LED module

- resistor paste firing

- IGBT/DBC

- Die attachment

Chamber:

- Chamber size: 350 x 350 x 70 mm (optional up to 120 mm)

- Chamber walls: Aluminium polished, easy to clean (optional: stainless steel)

Loading:

- Cover: opens and closed vertically (top loader)

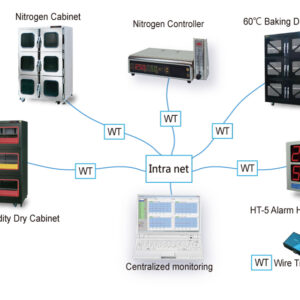

- Direct or remote control for automatically application (SPS, robotics,etc).

Ramp up rate: up to 150K/min.

Ramp down rate: up to 120K/min.

Heating:

- Bottom heating: 2 x 12 lamps crossed 18 kW

- Top heating: in request

Cooling:

- Chamber: by water cooled graphite plate 310 x 310 mm

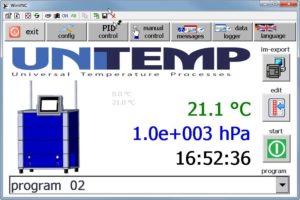

Process control:

- Control: SIMATIC SPS with touch panel 7″

- Software: process control, programming, recording and process

documentation. - 50 programs with 50 steps each storable

Process gases:

- 1 Mass Flow controller for 5 nolm (norm liter per minute) is standard

- Optional: up to 4 gas lines

Vacuum

with turbomolucularpump, vacuum valve and measurement for vacuum up to 10E-6 hPa

optional fore pump:

- MPC (Chemical resistant Membrane pump): 10 hPa. Monitored by manometer.

- RVP (Rotary vane pump): 10exp.-3 hPa. Vacuum sensor up to 10exp.-3 mbar

Connections:

- Power supply: 1 x [CEE 3 x 32 A / 3~ +N+ PE, 230 V>. Back side.

- Vacuum connector: KF 16

- Exhaust: KF16 rear site.

- gas line: 4 mm OD Swagelok compression fitting

Dimension/weight:

- Dimension: 540 mm x 690 mm x 890 mm (W x D x H)

- Weight: about 110 kg

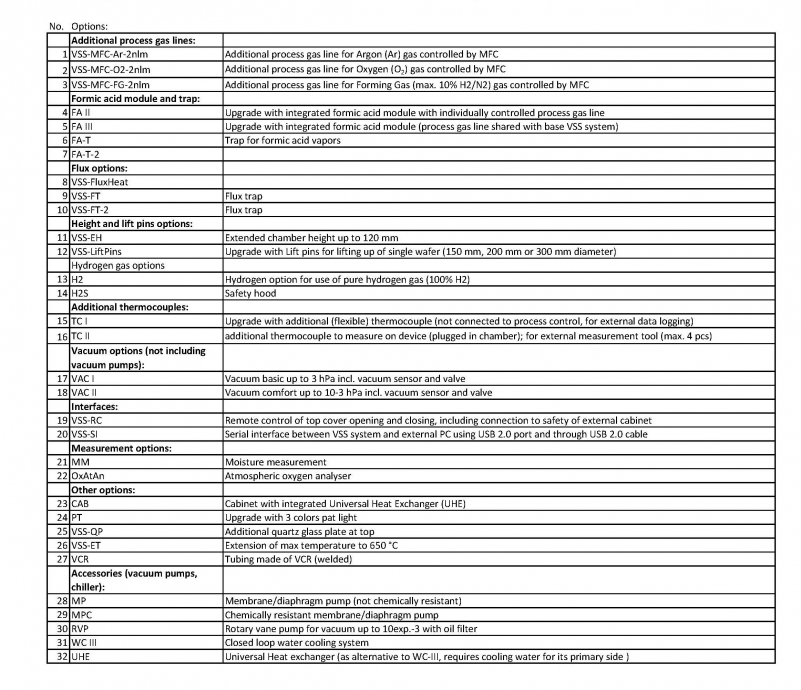

- CLICK HERE FOR ALL AVAILABLE OPTIONS.