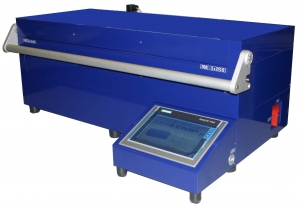

UniTemp RSS-160-S Reflow Solder System

Mini Vacuum Reflow Solder System

The reflow solder system is perfect for the following applications:

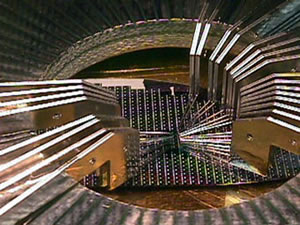

- flux-less soldering

- flip chip process

- adhesive bonding

- solder bump reflowing

- encapsulation of housings

- soldering of power devices

- heat treatment of semiconductor wafers

- prototype development

- quality control

Technical Data:

- heated area: 160 mm x 160 mm (= model RSS-160-S)

- chamber height: 40 mm (optional up to 80 mm)

- viewing window with 60 mm dia.

- Mass Flow controller for Nitrogen (5 nlm)

- vacuum atmosphere up to 10exp.-3 hPa (KF16 connector)

- temperature up to 400 °C (optional up to 500 °C)

- ramp up rate: better 100 K/minute

- ramp down rate: better 100 K/minute

- SIMATIC© process control with 50 programs and 50 steps each

- 7″ touch panel

- water cooled chamber (controlled and watched)

- electrical connection type: 230V, 2.4 kW or 115V, 1.2 kW

| Options and accessories: | |

|---|---|

| FA I | Formic acid module (separate module, not integrated) with Mass Flow Controller |

| FA II | integrated formic acid module with Mass Flow Controller |

| FA III | integrated formic acid module with shared Mass Flow Controller |

| MFC | additional Mass Flow Controller (max. 2 pcs) |

| RSS-EH | Chamber height 80mm instead of 40mm |

| RSS-H2 | Hydrogen Module: for using 100% Hydrogen incl. gas line with Mass Flow Controller |

| RSS-H2S | Safety device to prevent uncontrolled emission of Hydrogen |

| RSS-IL | Interlock mechanism during operation |

| RSS-TC | Additional thermocouple (max. 3 pc) |

| VAC I | Basic Vacuum up to 3 hPa, incl. vacuum sensor and valve, excl. pump |

| VAC II | Comfort Vacuum up to 10E-3 hPa, incl, vacuum sensor and valve, excl. pump |

| MP | Membrane/Diaphragm pump for vacuum up to 3 hPa |

| MPC | Chemical resistant membrane pump for vacuum up to 3 hPa |

| RVP | Rotary vane pump for vacuum up to 10E-3 hPa with oil filter |

| WC I | Closed loop water cooling system |

Download (information): RSS-110-S, RSS-160-S and RSS-210-S