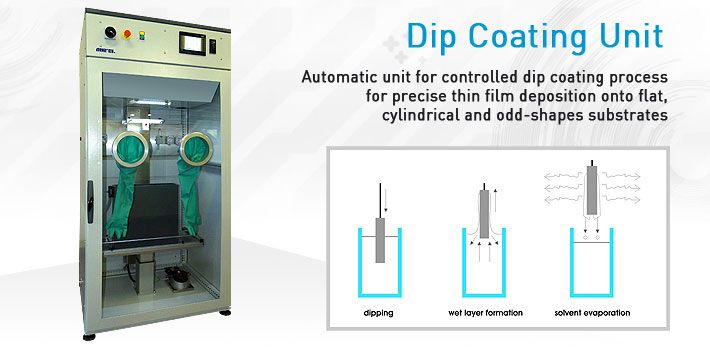

Automatic unit for controlled dip coating process for precise thin film deposition onto flat, cylindrical and odd-shapes substrates.

Applications

Dip coating refers to the immersing of a substrate into a tank containing coating material, removing the piece from the tank, and allowing it to drain.

The process is carried out with well-defined speed under controlled temperature and atmospheric conditions. The coating thickness is mainly defined by the withdrawal speed, by the solid content and the viscosity of the liquid. Owing to its simplicity, this method lends itself to automation.

Stage of Dip Coating

The dip coating process can be, generally, separated into 3 stages:

- Immersion: the substrate is immersed in the solution of the coating material at a constant speed preferably judder free

- Dwell time: the substrate remains fully immersed and motionless to allow for the coating material to apply itself to the substrate

- Withdrawal: the substrate is withdrawn at a constant speed to avoid any judders. The faster the substrate is withdrawn from the tank the thicker the coating material that will be applied to the board

Features

- Glovebox rack IP55

- Glovebox gloves 8” in Nitrile

- Motorized vertical stroke

- Process parameters adjustment by touch-screen panel

- Up to 20 storable recepies

- Connection for aspiration

- Connection for controlled atmosphere

- Humidity measure and control system

- Tank holder with adjustable level

Specifications

- Immersion speed range: 1-20 mm/sec

- Withdrawal speed range: 1-20 mm/sec

- Vertical motorized stroke: 600 mm

- Glovebox rack dimensions: 1000x800x1800H mm

- Max tank dimension: 700x200x500H mm

- Tank material: PVC or glass

- Glovebox gloves: 8″ – in nitrile

- Controlled humidity range: 10% – 50% RH

- Safety class: IP55

- Power supply: 220V-50 Hz-3A