AUREL Automation has been specializing for years in Automatic Screen Printing Lines design and production. Most of its products can be customized according to different needs. One of the last born is an Automatic Screen Printing Line for Chip Resistor.

AUREL’s approach starts from a preliminary study of the project to identify the key-points and share a common line with the customer.

It is fundamental to know the production process where the line will be installed in order to build solid foundation and, mainly, define the specifications needful for making an automation that ensures production requirements.

The most important requirements are productivity rates, for instance the number of pieces per hour, and repeatability and quality rates of the product (e.g. FPY, First Pass Yield).

This phase has to be considered as an exchange of information between the manufacturer and the customer.

AUREL, thanks to its large experience and several configurations, is often able to give suggestions to the customer that aim at improving the automation itself, but also, as natural consequence, to optimize the whole production process.

The Chip Resistor Line consists of:

- Automatic loader from stack magazine;

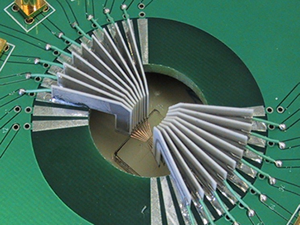

- High precision screen printer with mechanical and optical centering of the substrate;

- Robot for automatic loading of the substrates onto the conveyor of the dryer oven;

- 3 meters dryer oven;

- Withdrawal system from the dryer conveyor into 2 stack magazines with PRS (Pattern Recognition System).

The Power of Customization

The handling and centering systems have been designed to manage ultra-thin substrates (up to 0.25 mm) with prescribing and printing accurately miniaturized chips up to 01005 standard thanks to the optical alignment system.

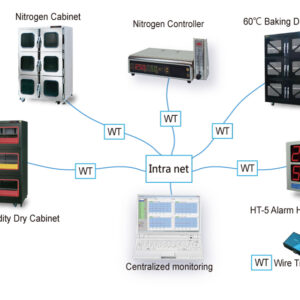

The line is fully PC controlled to monitor all process parameters and implement data store in the corporate network.

The flexibility of the solution allows the customer to use the lines for printing different substrate sizes, with automatic flipping over in case of double side printing.

Aurel Automation is directly involved both in the mechanical and software development and thanks to that it has the possibility to work in an “open system” to get design optimization by performing daily trials with a step-by-step approach.

The result is a flexible, integrable and efficient solution that perfectly meets the industrial current situation, in which the demand volume is definitely lower and the differentiation of the product is always growing.