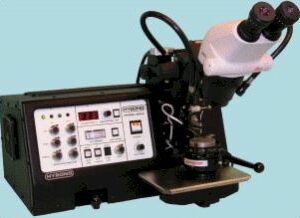

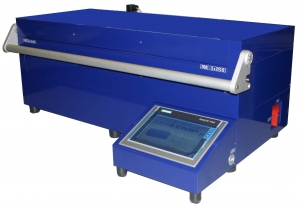

Model 676 Digital Thermosonic Wedge Bonder

Model 676 is a Deep Access, Long Reach Thermosonic Wedge Bonder for wire diameters from 0.5 to 3.0 mil (12 to 76µm) and ribbon up to 1.0 x 12.0 mil (25 x 300µm) featuring Hybond’s unique Soft Touch™ energy system.

The 676 was specifically designed for applications that require bonding at extreme height differences between 1st and 2nd bond and bonding wires to sensitive devices such as gallium arsenide FET’s and LED’s.

Model 676’s motorized wire feed and wire/ribbon clamping system provide superior wire/ribbon control and also allow the operator to increase or decrease tail length in 1 mil (25µm) increments at a touch of a switch.

The amount of clamp “pull-back” required to break the wire at final bond may also be varied in relation to wire elasticity allowing the use of softer wires (higher elongation) than conventionally used in wedge bonding. 676 shows actual units for set up of bond parameters.

Standard Features

- Hybond Soft Touch energy system

- 100 Bond schedules programmable in non-volatile memory

- Selectable / adjustable reset heights (constant or adaptive)

- 1-2-2, 1-2-1 & 1-1-2 auto stitch or manual continuous stitch in manual & auto modes

- Sensor controlled bond actuation for variable bonding height

- 0.740 inch max. vertical bonding window

- Deep vertical access of 0.53″ (1,34cm)

- Static dissipative enclosure

- Horizontal reach of 6.5″ (16,51cm)

- Programmable loop and search heights

- Built-in digital temperature controller

- High / low power PLL ultrasonic generator

- Swing-away wire clamp assembly

- 0.5 and 2 inch spool mounts

- Z-axis movement controlled by footswitches or manipulator

- Motorized Z-axis control in auto and manual modes

Optional Features

- Leica Stereo Zoom microscope (OP-06S6)

- Nikon SMZ660 microscope (OP-06A)

- Dual fiber-optic illuminator (OP-08A)

- 8:1 X-Y Manipulator (OP-30A)

- Tool heater with temperature controller (OP-31)

- Heated Ultrasonic Transducer (OP-82)

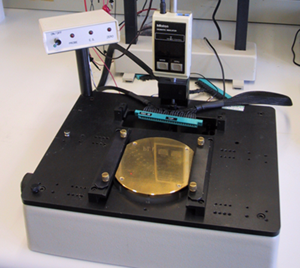

- 2.125″ diameter heated workstage(WST-15A)

- 4″ x 6″ heated workstage (WST-19A)

- 10″ x 6″ heated workstage (WST-65)

- Wire & Ball tool as ordered per application

| Specification: | |

|---|---|

| Ultrasonic System: | PLL self-tuning, 62.5 KHz (±2.5KHz) nominal |

| Ultrasonic Power Range: | 0- 0.2 watt on Low setting (default), 0- 2 watts on High setting |

| Bond Time Range: | 0– 900 mSec |

| Bond Force Range: | 12– 250 grams |

| Temperature Control Range: | Ambient to 250° C |

| Bondable Wire Diameters: | 0.5 to 3.0 mils (12.7 to 76,2 µm) |

| Bondable Ribbon Dimensions: | 1 x 20.0 mils (25,4 to 510 µm) |

| Bondable Wire/Ribbon Materials: | Gold, (aluminum and gold coated copper for wedge bonder) |

| Bond Head Movement: | Motorized (servo); activated by manipulator switches or footswitches |

| Bond Actuation: | By sensor at bond surface contact |

| Z Axis Travel: | 0.75 in (1,90 cm) |

| Vertical Bonding Window: | 0.74 in (1,88 cm) |

| Table Motion: | 4:1, manual |

| Input Power Requirements: | 90- 260 VAC 50/60 Hz @ 10A max |

| Minimum Bench Space Required: | 20″x20″ (50,8cmx50,8cm) |

| Unit Weight/Shipping Weight: | 70 lbs (31,8Kg)/150 lbs. Shipping weight will vary |

| Industry Standards: | CE certified |

Download (information): MODEL 676