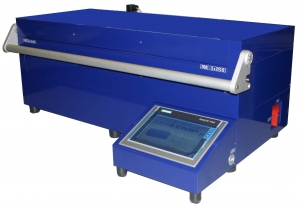

Printing area up to 800 x 600 mm. Special fixture for flexible substrates. Roll-to-Roll automation.

Standard Features

- Double squeegee head for the use of metal squeegees or rubber squeegees

- Squeegee drive actuator with DC motor and very smooth movement of the printing head

- Printing mode: Contact, Off Contact, Single Print, Double Print, Print & Flood, Delay after Print

- High precision and repeatability for fine-pitch and fine-line printing

- Motorized squeegee with programmable printing pressure and down stop

- X–Y–q adjustments by centesimal micrometers

- Motorized and programmable screen lift movement (Z axis) for the function “slow snap–off” very important on fine line printing

- PC control, Windows SW with menu programming of all printing parameters, diagnostic, data storage

- Screen holder and printing head lift for easy set up and cleaning

Options

- Vacuum fixture for thin foils hold down

- Holes metallization or holes filling

- Clima control

- Vision system

- Automatic stencil cleaning

- PCB or foil cleaning station

- Roll-to-Roll printing

- Automatic handling system

| Specifications | |

|---|---|

| Print area | 790 x 600 mm (MAX) |

| Printing Stroke | 840 mm |

| Max squeegee width | 620 mm |

| Screen size | 1000 x 850 mm O.D. |

| Work holder table size | 840 x 640 mm |

| Vacuum area | 820 x 620 mm |

| Carriage repeatable | 0.025 mm |

| X-Y adjustment | 12.5 mm |

| Z adjustment (Screen height) | ± 6 mm |

| Theta adjustment (Rotation) | ± 3 degrees |

| Squeegee speed | 0 ÷ 300 mm/sec |

| Squeegee pressure | 1 ÷ 16 Kg |

| Height with cover | 1880 mm |

| Height to substrate | 900 mm |

| Approx. Weight | 600 Kg |

| Compressed air | 5 bar 100 NI/min |

| Power | 240V 1000W |

Download (information): Model VS2025