The new AUREL C1010R is made for precision printing combined with a high throughput.

Cycle times are drastically reduced. Valuable production time is used for the process, while loading, inspection (vision or manual) printing and unloading is done in parallel.

The machine needs less floor space than a comparable linear solution. So it can fit, where manual machines have been used before.

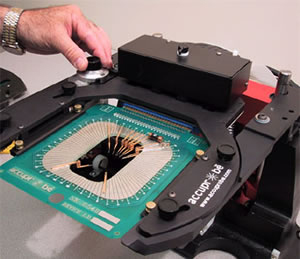

HEAD

- Manual or Automatic Loading

- Collocating Robot

- Drying/Curing

- Automatic Reloader

FEATURES

- Modular design for manual or automatic substrate handling

- Precision rotating table with 4 steps and accuracy of ± 0.015 mm

- Based on standard AUREL C1010 wich is fieldproven in many installations

- All axis motor driven, controlled and programmable

- PC controls with menu guidance with parameter controls and printout of production data

- Table loading into loose nests, precision centering is done only in the printing position

- VISION centering optional

- Squeegee pressure and parallelism controls and two independent height adjustment for print and flood with 0.01 increments

- DC motor drives for smooth movement ot the printing head

- Z axis motorized and programmable for controlled snap-off

- Automatic squeegee and screen holder lift for easy machine set up and cleaning

- Programmable motorized unloading arm with gripper head for collocating the substrates over the dryer conveyor

- Vacuum pump for substrate hold down included in the machine

| Specifications | |

|---|---|

| Max print area | 100 x 150 mm |

| Max squeegee width | 200 mm |

| Screen size (I.D.) | 12″ x 12″ |

| X-Y adjustment | 25 mm |

| Z adjustment (screen height) | 12 mm |

| Theta adjustment (rotation) | ± 5 degrees |

| Print stroke | 50 to 210 mm |

| Squeegee speed | 0 to 300 mm/s |

| Squeegee pressure | 0 to 12 Kg |

| Repeatable | ± 0.015 mm |

| Squeegee and screen parallel | ± 0.01/100 mm |

| Cycle rate | max 1000 PPH |

| Dimensions | 1730 x 1385 x 1430H mm |

| Approx. Weight | 450 Kg |

| Compressed Air | 5 Ate – 150 Nl/min |

| Power | 380V 3+N+T 5A 50 Hz |

Related contents