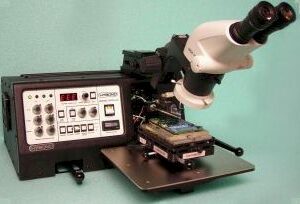

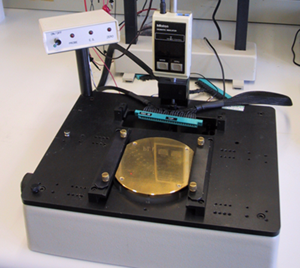

Model 572A Thermosonic Wedge Bonder

Imitated but never duplicated, Hybond’s exclusive Soft Touch™ force ramping system bonds effectively with less trauma to sensitive materials like GaAs and InP.

Superior wire control is provided by the motorized feed system which features clamps capable of feeding wire and ribbon, dial adjustable tail length, switch for manual tail length adjustment and clamp pull back dial adjustment to allow bonding and cutting of softer (higher elongation) wires than conventionally used for wedge bonding.

Model 572A includes front panel independent controls for 1st and 2nd bond U/S, Time & Force as well as for the built in workstage temperature controller.

The 572A has a proven track record of safe and effective wire and ribbon bonding worldwide.

Standard Features

- Hybond Soft Touch energy system

- Independent Z-axis lever for bonding tool control

- Motorized vertical wire feed

- 1-1-2, 1-2-2 & 1-2-1 stitch capability

- 0.5 and 2 inch spool mounts

- Loop height control adjustment

- Front panel wire feed control for manual tail adjustment

- Swing-away wire clamp assembly

- Deep vertical access of 0.59″ (1,49cm)

- Horizontal reach of 3.5″ (8,89cm)

- Deep access Wire-In-Tool 90° wire feed

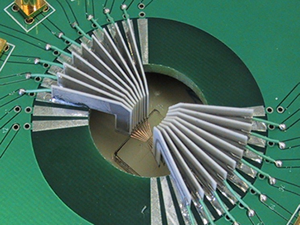

- Wire and ribbon bonding capability

- Independent control of 1st & 2nd bond parameters

- Tail length adjustable

- Audio & visual bond sequence fault indicators

- 6 x 8.5 inch work platform

- LED display of work stage temperature

- Infinite angle microscope mounting

- Front panel ultrasonic test button

Optional Features

- Leica Stereo Zoom microscope (OP-06S6T)

- Nikon SMZ660 microscope (OP-06A)

- Dual fiber-optic illuminator (OP-08A)

- 240 VAC 50/60 Hz input wiring (OP-12)

- 8:1 X-Y Manipulator (OP-30)

- Tool heater with temperature controller (OP-31)

- Heated Ultrasonic Transducer (OP-83)

- High & low ultrasonic power (OP-44)

- 2.125″ diameter heated workstage (WST-15A)

- 4″ x 4″ heated workstage (WST-19B)

| Specification: | |

|---|---|

| Ultrasonic System: | PLL self-tuning, 62.5 KHz (±2.5KHz) nominal |

| Ultrasonic Power Range: | 0-1 watt on Low setting (default), 0-2 watts on High setting |

| Bond Time Range: | 10– 400 mSec |

| Bond Force Range: | 15– 150 grams |

| Temperature Control Range: | Ambient to 250° C |

| Bondable Wire Diameters: | 0.7 to 2.0 mils (18 to 50,8 µm) |

| Bondable Ribbon Dimensions: | Up to 1 x 10 mils (25,4 x 254 µm) |

| Bondable Wire /Ribbon Materials: | Gold and aluminum |

| Bond Head Movement: | Manual |

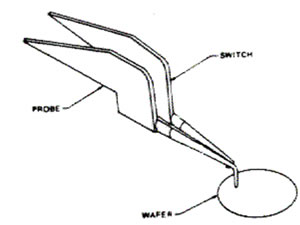

| Bond Actuation: | Switch at fixed height, actuated by lever |

| Z Axis Travel: | 0.5 in (1,20 cm) maximum |

| Vertical Bonding Window: | 60 -100 mils (152-254 µm) |

| Table Motion: | 4:1, manual |

| Input Power Requirements: | 120 VAC 50/60 Hz @ 10A (std) or 240 VAC 50/60 Hz @ 5A |

| Minimum Bench Space Required: | 20″x20″ (50,8cmx50,8cm) |

| Unit Weight/Shipping Weight: | 55/135 lbs. (24,9/61,4 Kg). Shipping weight will vary. |

| Industry Standards: | CE certified |

Download (information): MODEL 572A