This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

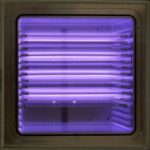

Plasma Cleaning Systems

Model YES-G-Series

Model YES- G1000-LMC

The use of plasma is an effective way to clean without using hazardous solvents. Plasma is an ionized gas  capable of conducting electricity and absorbing energy from an electrical supply. When a gas absorbs electrical energy, its temperature increases causing the ions to vibrate faster and “scrub” a surface.

capable of conducting electricity and absorbing energy from an electrical supply. When a gas absorbs electrical energy, its temperature increases causing the ions to vibrate faster and “scrub” a surface.

Typically, plasma is created in a low-pressure environment. Plasma cleaning systems are an effective way to remove small amounts of contaminants from a substrate surface. (For removing thick photoresist layers, see our Plasma Photoresist Strip/Descum Systems).

Typical Applications:

- Wire bond surface preparation

- Removing contaminants (flux) or sterilizing a surface

- Promoting adhesion between two surfaces

- Controlling surface tension to achieve either a hydrophobic or hydrophilic surface

- Increasing biocompatibility

- Improving polymer performance through cross-linking to decrease friction that wears out devices

n semiconductor processing, plasma cleaning is commonly used to prepare a wafer surface prior to wire bonding. Removing contamination (flux) strengthens the bond adhesion, which helps extend device reliability and longevity.

In biomedical applications, plasma cleaning is useful for achieving compatibility between synthetic biomaterials and natural tissues. Surface modification minimizes adverse reactions such as inflammation, infection, and thrombosis formation.

Benefits of Low Frequency

Plasma processing equipment commonly uses RF to generate gas plasma. A variety of parameters can affect the physical characteristics of plasma and subsequently affect the surface chemistry obtained by plasma modification. In order to achieve uniform, superior results, Yield Engineering Systems recommends low frequency plasma (40-50 kHz) over high frequency plasma (13.56 MHz or 2.54 GHz) for the following reasons:

- Higher Ion Density. Low frequency plasma provides more energy per square inch than high frequency cleaning. While this may seem counterintuitive, high frequency plasma cleaning systems actually lose considerable energy through heat loss. Energy loss with a 13.56 MHz system is up to 850 times greater than with a 40 kHz system.

- Increased Efficiency. The efficiency of a plasma system is the ratio of the energy used in producing the plasma vs. the energy dissipated in losses such as heat. A low frequency plasma system acts like a perfect capacitor with infinite capacitive impedance, or zero current drain when in standby mode. Current applied across the capacitive pair (electrodes) causes the gas to ionize, and the impedance is bridged causing current flow (plasma) between the electrodes.

- Better Uniformity. Low frequency systems have no “shadowing,” which occurs when samples on upper shelves form a mask that prevents plasma from reaching samples on the lower shelves.

Choosing a Plasma Cleaning System

Choosing the appropriate system and frequency for your specific process depends on multiple factors. It’s important to note that a higher RF power doesn’t necessarily equate to higher plasma density (especially at low pressures). The additional power is often wasted through increased ion bombardment and through the creation of hot electrons, not in promoting ionization. Also, if the average voltage between the plasma and chamber walls (plasma potential) becomes too high, it can cause sputtering and contamination to substrates.

For a system specifically suited to plasma cleaning/descum applications, please check out the YES-G500 and YES-G1000.

No products were found matching your selection.