YES PB-HV Series (manual load)

YES-PB8 High Vac Specs (up to 200mm wafers)

YES-PB12 High Vac Specs (up to 300mm wafers)

Process Management Software

Stainless Steel Process Cassettes

The YES-PB-HV series of manual load high vacuum ovens is designed for today’s most demanding MEMS and semiconductor process applications. These tools are designed to ensure moisture and hydrogen removal using high vacuum (10-5) and high temperature (up to 450°C). Our patented nitrogen purge precedes process ramp and creates a successful procedure for improved MEMS lifetime and performance.

Nitrogen purge also results in a low oxygen environment which allows for proper copper annealing or aluminum annealing.

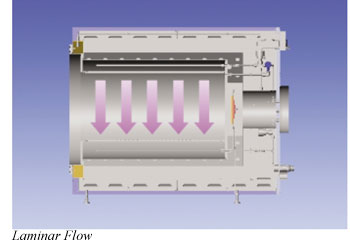

Laminar Flow Technology

YES PB-HV high vacuum ovens offer vertical laminar airflow paired with a unique cooling package to cool the chamber. The vertical laminar flow carries particulates away so they won’t deposit onto wafers. Directing the airflow so it streams from the top of the system and out the bottom ensures there’s no air turbulence, allowing particle reduction in most applications.

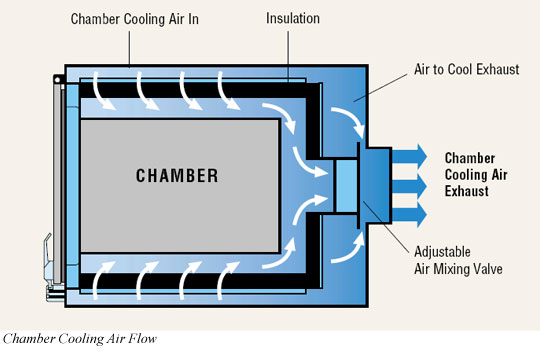

Unique Cooling Package

The YES-PB-HV Series cooling package allows for faster chamber cooling times as well as temperature uniformity control throughout the process. Adjustable air mixing ratio for chamber cooling adapts the tool for best performance over a broad range of operating temperatures. The design allows the process engineer total control of ramp down rates within the tool’s specifications. The cooling package only uses air, no water.

Applications

Wafer Dehydration – The moisture on the surface of wafers will cause unintended reactions with various deposition steps. These reactions result in unstable surface which degrade over time. Vacuum dehydration provides a clean stable starting surface resulting in superior films.

The process begins with vacuum cycle purges to remove oxygen and water vapor followed by a continuous horizontal laminar flow of up to four process gasses. The laminar flow of gas can be maintained during a recipe-driven temperature profile. Operating temperatures are 150°C to 450°C; laminar flow pressure range is 0.50-500 Torr. The tool is also capable of evacuation down to 1E-5 Torr using a vacuum turbo pump.

The YES-PB-HV gives engineers moisture resistant surface modification and increased time available between process steps.

Getter Activation – Getters are used to scavenge unwanted gases in many applications. In MEMS devices, getters may be used to tie up excess moisture or hydrogen which may interfere with the long term operation of the device. Activating the getter material involves high temperature and high vacuum processing to ensure the material starts as moisture / hydrogen-free as possible. 400°C and high vacuum (10-5) removes moisture/hydrogen gas from both wafers and getters at the same time.

Metal Annealing – Annealing is a heat treatment where the microstructure of a material is altered, causing changes in its properties such as strength and hardness. In the semiconductor industry, silicon wafers are annealed so that dopant atoms (such as boron, phosphorus or arsenic), can be incorporated in substitutional positions into the crystal lattice, which drastically changes the electrical properties of the semiconducting material.

In the case of copper, adding an anneal step:

- Improves properties of the copper layer

- Increases grain size for faster polishing

- Provides better conductivity

- Reduces surface tension

- Minimizes electromigration

- Allows a consistent CMP rate across the wafer

Thermal treatment of Thin Film Resistors – Thin film resistors can change properties rapidly as they age unless they are properly thermally treated. The process stabilizes the crystal grain and ensures long term predictable behavior.