UniTemp VPO-300 (automatic vertical open/close)

Vacuum Process Oven for up to 300 x 300 mm substrate size and temperature up to 1000 °C

Lamp heated rapid thermal annealing RTA and rapid thermal processing RTP equipment are using lamp heating in order to ramp up and cool down semiconductor wafers pretty fast. This equipment is therefore mainly used for applications where the substrate needs to be brought to a certain temperature just only for short time. The high ramp rates allow a short overall process time and keep the thermal budget (this is the total time of a wafer, being exposed to high temperature) of the wafer low. Because of the design of the heaters, these RTA and RTP tools are used mainly for single wafer treatment. Wafers have to be treated one by one. This is not as important as for other batch thermal processes, which use vertical furnaces and horizontal furnaces, because the process time is very short anyway. However wafer handling takes a substantial part of process time.

The VPO-300 is a cold wall oven.

UniTemp RTP furnaces offer a unique lamp arrangement with upper and lower cross lamp arrays. The temperature distribution tool provides outstanding and unparalleled temperature uniformity resulting in process repeatability.

Application:

Perfect for wafer up to 300 mm or substrates up to 300 x 300 mm.

Through the chamber walls there can be led different feed throughs, like a window for optical measurement tools, thermocouple feed through, gas inlets, etc.

The process cycles are very short due to fast reaching of vacuum with 10E -3 hPa.

Here are the most feasible applications:

Processes using also other contaminating processes possible and all other applications of a RTP/RTA oven are obligatory,like:

- Annealing processes

- Rapid Thermal Processes

- SiAu, SiAl, SiMo alloying

- low k dielectrics

- post implanting annealing

Chamber:

- Chamber size: 350 x 350 x 50 mm

- Loading area: 300 x 300 mm

- chamber height: 50 mm (optional: chamber height 120 mm)

- Chamber walls: Aluminum polished, easy to clean (optional: stainless steel)

Loading:

- Cover opens and closes vertically

- Direct or remote control for automatically application on request (SPS, robotics,etc).

Heating:

- Bottom heating: Infrared lamps crossed 21 kW

- Upper heating: Infrared lamps crossed 21 kW (selectable)

Cooling:

- Chamber: Gas N2

Process control:

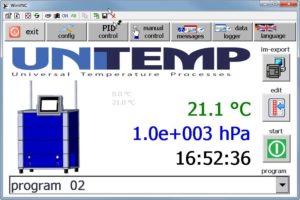

- Control: SIMATIC SPS (PLC) with 7″ touch panel

- 50 programs with 50 steps each storable

Process gases:

- 1 Mass Flow controller for 5 nlm (=norm liter per minute) is standard

- Optional: up to add. 3 gas lines (Nitrogen, Argon, Helium, Oxygen, optionally

Hydrogen)

Vacuum (optional):

- MP (Membrane pump

- RVP (Rotary vane pump): 10E -3 hPa. Vacuum sensor up to 10E -3 hPa

- other pumps on request

Connections:

- Power 2 x (400/230V, 21 kW)

- Vacuum connector: KF 16/25

- Exhaust: KF16 rear site

- Gas lines: Swagelok 6 mm compression fitting

- Cooling water supply: 10 mm/12mm

- Compressed dry air (CDA), 6 mm OD, 5 – 6 bar

Dimension/weight:

- Dimension: 540 x 690 x 890 mm (w x d x h)

- Weight: about 100 kg

Download (information): VPO-300 + 300-HV

Download (information): UniTemp Safety Hood

Options and accessories (PDF) VPO

| VPO-300 Options and accessories | |

|---|---|

| VPO-300 | Basic unit |

| VPO-300-HV | Basic unit "High Vacuum" version |

| VPO-MFC | Additional gas line with mass flow controller (max. 3 gas lines) |

| VPO-RVP | Rotary vane pump for vacuum up to 10exp-3 hPa with oil filter |

| VPO-SS | Chamber made of stainless steel instead of aluminum (polished) 50 mm |

| VPO-H2 | Hydrogen module |

| VPO-GP | Graphite Plate 3 mm thick |

| VPO-QP | Quartz plate for separation of the top lamp area |

| VPO-QH | Quartz universal holder for 100 mm up to 300 mm wafer size (star) |

| VPO-TC | additional thermocouple to measure on device (plugged in chamber); for external measurement tool max. 4 pcs |

| WC III | Closed loop water cooling system |

| vacuum | We offer different vacuum pumps and vacuum equipment |

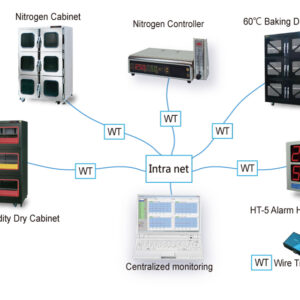

| VPO-SI | Serial interface between VPO system and external PC using USB 2.0 port and through USB 2.0 cable |

| VPO-RC | Remote control of top cover and closing, including connection to safety of external cabinet |