Automatic lines for pressure sensors, proximity switch, biosensors, RFID, position sensors, piezo and ultrasonic ceramic.

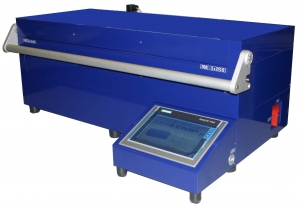

VS1520MM Line

Automatic Printing and Drying Line for ceramic substrate 4″x 4″ and 4″x 6″. Special solutions for high accuracy. Smooth handling for very thin substrates (0,2-0,3 mm).

Substrates cleaning with no-touch device, Vision alignment by X-Y moving camera, through-holes metallization with PHM system PC programmable, PPI software for Post Print inspection, Dryer with finger conveyor for double sided substrates, loader and unloader with cassette and/or stack

magazines.

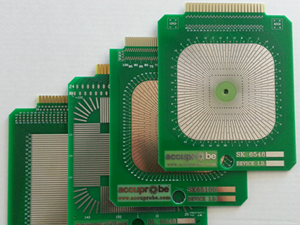

C1010RM line

Automatic loading with multi cassette system, screen printer with rotating table, vision alignment option, PPI software for Post Print inspection, Oven Loading-Unloading by programmable robot with finger head, Reloading after Drying into cassette with vision system to automatically recognize the parts on the conveyor belt.

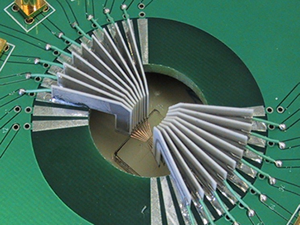

C105R High Speed

C105R High speed screen printer for small ceramic components, piezo and ultrasonic sensors. High speed rotary table, up to 3600 parts/h.

Automatic loading from stack magazine or from vibratory, cleaning, printing, PPI software for Post Print Inspection, automatic unloading. Integration of conveyors, drying and firing ovens, handling.

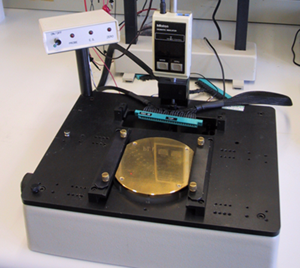

ALS300MM line

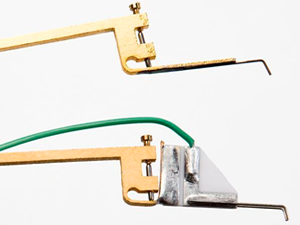

Automatic Line for Testing and Calibration. Transport system for the indexing of palettes with an array of devices, heating and cooling zones, testing areas under pressure, gas, humidity or other custom requirements.

Calibration of the compensating resistors by Aurel Nd YAG Laser Generator, Vision system and pattern recognition or CRS Chip Recognition System, programmable instruments IEEE488 bus, PC control, Windows software for data collecting, statistics and system control.

Marking Lasers

ALS6100 Laser Marking System, Nd YAG Laser generator for marking different materials as plastics, PCB, Stainless steel, aluminum, for flat and round surfaces or continuous tape.

Download (information): Sensors manufacturing machines